18 • ASIAN TIMBER • SEPTEMBER/OCTOBER 2002

Special Report

Low-cost approach to logging

By Markku Ranin

F

orest companies around the world

seek to leave all forest work to

private contractors. The rationale

is that companies want to concentrate

their limited investments in what they

know best, whether they are in the

business of sawing, peeling or chipping

for boards and pulp. Cyclical variations

in market demand are easier to control if

the labour-intensive forest work is left in

private hands.

In Southeast Asia, in particular, it is vital

to create job opportunities to maintain

social peace and to promote private

entrepreneurs. Privatisation of road

transportation of logs has been well

accepted and investment in one or even

several trucks is within financial reach of

these new businesses.

Wheel tractors and forest trailers offer

a new low investment solution to log

forwarding. Simple to operate and with

little need for servicing, forest trailers are

now an affordable choice where private

contractors are encouraged to take over

all aspects of forest work. For the price of

one traditional forwarder one can buy five

trailers - each with close to the same

carrying capacity.

Cheap to own - cheap to

operate

Wheel tractors and flatbed trailers have

long been used in oil palm plantations.

They are used to carry the heavy nuts to

the roadside where they are then loaded

to trucks. Similarly, wheel tractors are now

emerging in forest work for all the same

reasons. It is easy to find skilled men to

operate these forwarders as there are

many who master the articulated tractor/

trailer link and can do servicing to wheel

tractors.

Trailers’ loaders are similarly easy to

operate as controls function exactly like

the ones in excavators. A high reliability

is achieved when in the case of engine

trouble only the wheel tractor needs to be

replaced without further interruption to the

forwarding work.

Forest trailers typically need no

modification before being fitted to a

wheel tractor. The grapple loader with

a rotator, hydraulic support legs and the

hydraulic 4-WD drive to the low ground

pressure balloon tires are all powered

by a tiny portable hydraulic pump that

fits nicely to the PTO output of the

tractor. Hydraulic control levers are

portable and just lifted to a suitable

place near the tractor driver.

They also make good road speeds, up

to 40 km/h fully laden, making it possible

to avoid reloading and delivering logs

direct to the mill if distance is a reasonable

10km or less. It has been noted with

delight that the road speed allows all

machinery to be taken to the

campgrounds for the night for security

reasons and not left in the dark forests on

their own.

Forest forwarding work carried out in

Indonesian acacia plantations have

shown lower than expected costs in

hauling logs to the roadside over

distances that vary from 100 m to 400

m. Operating and investment costs have

been well below US$10 per hour or less

than US$1.5 for each m

3

of wood

carried.

With the low investment level -

including cheap freight costs as one

can fit four units into a single 40ft

container - and ease of operation and

service, forest trailers or “ants” are

expected to make deep inroads in large

numbers into the forest communities in

Asia.

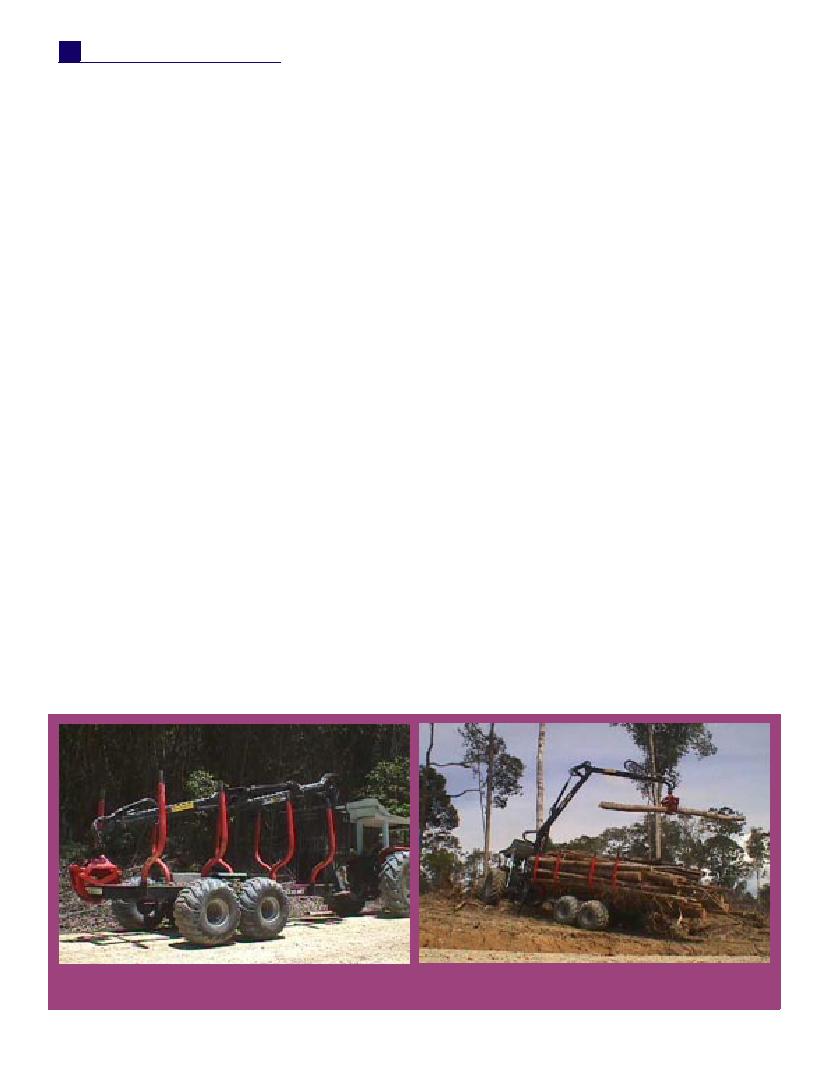

Nokka trailers were lengthened by 3 feet and fitted with an extra pair

of side poles to accommodate two tiers of short logs.

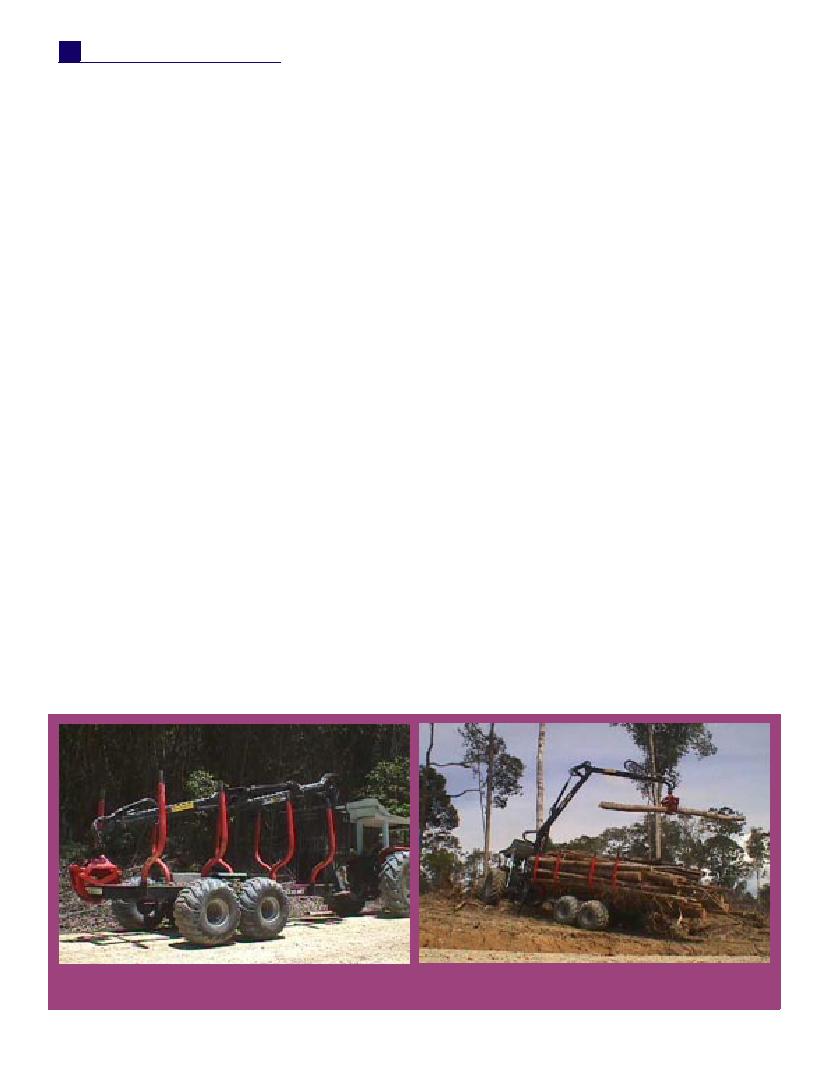

Nokka can take full 12 tons of logs whether they are short or long.

Designed primarily for plantations, the trailer is here loading mixed

tropical logs in Sumatra.